Nota bene: All products in this article are independently selected and vetted by InsideHook editors. If you buy something, we may earn an affiliate commission.

This is part of InsideHook’s list of The 100 Best American-Made Products, a celebration of the gear, clothes and goods that make up our lives, and are the life’s work of our fellow Americans.

“As curious, passionate designers and product makers, the idea of doing it yourself always is the ultimate dream,” says Kyle Fitzgibbons, chief creative officer at Buck Mason.

Fitzgibbons is referring to Buck Mason Knitting Mills located in Eastern Pennsylvania, where the Venice Beach-founded brand produces its Slub Classic Tee along with its Pima and Toughknit T-shirts. About four years ago, he says the brand became excited about the prospect of owning a factory.

“We were looking in Los Angeles, we were looking at the Carolinas, we were looking in Texas,” he explains. “At that time, the cut-and-sew T-shirt side of our business had been scaling and growing.”

After about three years, the company received a call from a friend who alerted them of a small factory in Mohnton, Pennsylvania and an accompanying mill in the neighboring town of Shillington. The facility — which originally opened in 1873 and produced hats, then in the early 1900s switched to sewing knitwear — had just shut down after 150 years. Buck Mason acquired the historic factory, the mill and its experienced workforce in 2023.

“I would say one of the greatest things about the factory and mill is not the land that we bought or even the machines that we bought, but it’s the employees that came with that purchase that get to be Buck Mason employees,” adds Fitzgibbons. “Now we have a legacy of knowledge and information. It’s not just about the machines, but about the process of American-made goods and how to do that in a way that not only meets the needs of the brand but also meets the needs of the customer.”

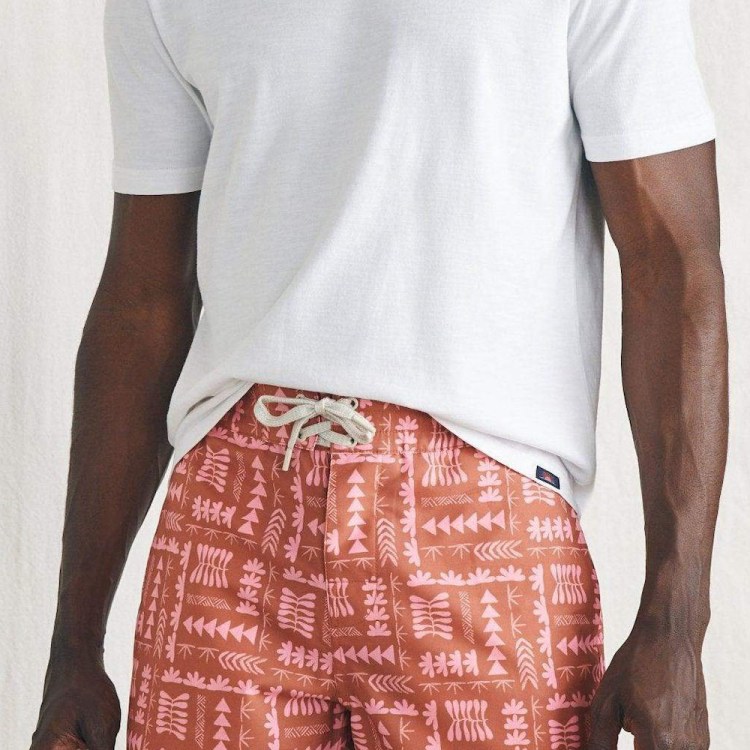

Buck Mason’s Slub, Toughknit and Pima tees are not only sewn in the U.S., but proudly grown here too. The company uses all-American cotton from a few farms in the U.S., mainly Davis Farms located in Georgia and the Carolinas.

In terms of design, Buck Mason has delved into the archives. According to Fitzgibbons, the pinnacle of the American T-shirt spans three decades, starting in the 1930s with America’s foray into sportswear, then well into the ‘50s, when the popularity of the T-shirt grew exponentially.

“A lot of what we referenced was American cotton that was spun and knitted in the U.S. during the ‘30, the ‘40s and ‘50s,” he says. “A lot of what we’re looking at is old T-shirts. We love how these garments have aged over time — some of the texture and the imperfections that come from that.”

The brand’s Slub Classic Tee, in particular, is constructed from an “interesting fabric.”

“The way to affect the density of a fabric has to do with the number of needles that are in the tubular knitting machine,” he notes. “So what we’ve done with that [slub] fabric is we’ve removed a bunch of needles, so you get kind of an open, more gauzy look and feel. You also get more of the irregularity of the texture.”

So how does the Buck Mason Slub Classic Tee stand out against the blinding swarm of basic white T-shirts on the market these days? “Some would argue the T-shirt is one of the most ubiquitous things, alongside the jean, in American fashion. I think we can all point to why ours is better or different, or more valuable or more interesting. But I think ultimately it’s what I believe in most: the passion of passionate people,” says Fitzgibbons.

“I’ve gotten to watch over the last few years that team — from designers and pattern makers and fabric builders and product builders — bring that to life and touch every part of it. From drafting the pattern to making the T-shirts, to making the fabric, we’ve considered everything within that process. We’ve done the best we can to make a product that we can be proud of, in that T-shirt and in every other T-shirt we make.”

We've put in the work researching, reviewing and rounding up all the shirts, jackets, shoes and accessories you'll need this season, whether it's for yourself or for gifting purposes. Sign up here for weekly style inspo direct to your inbox.