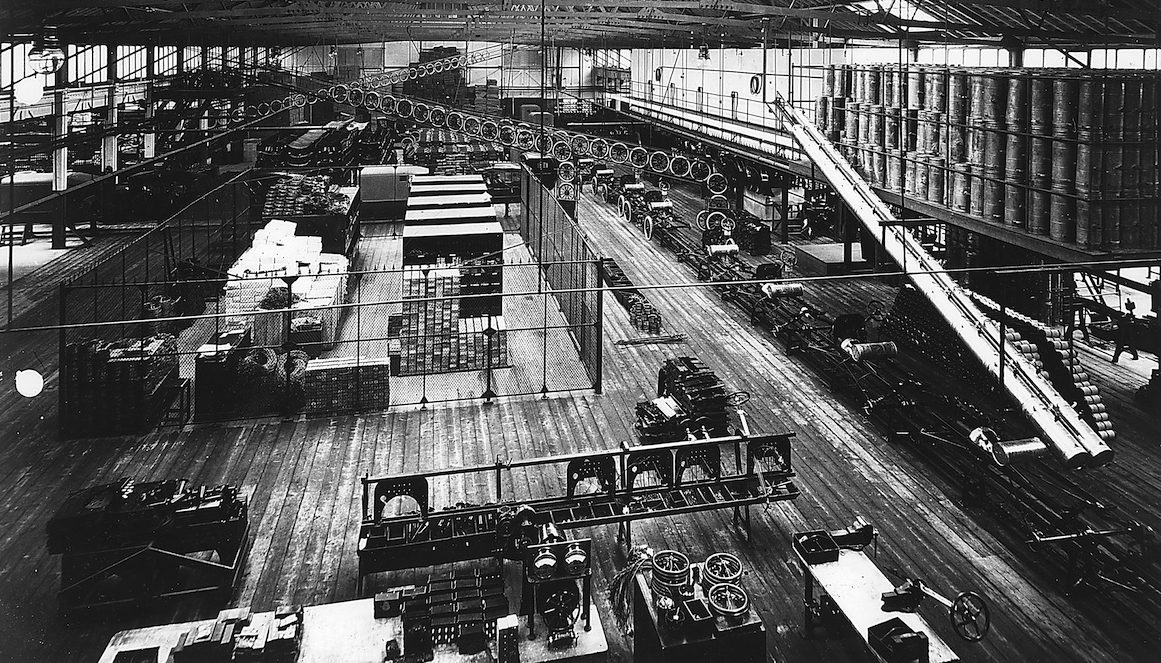

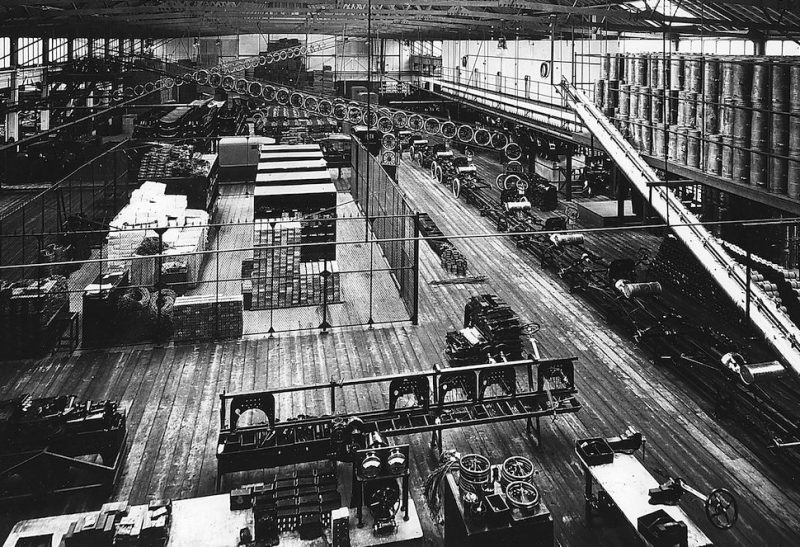

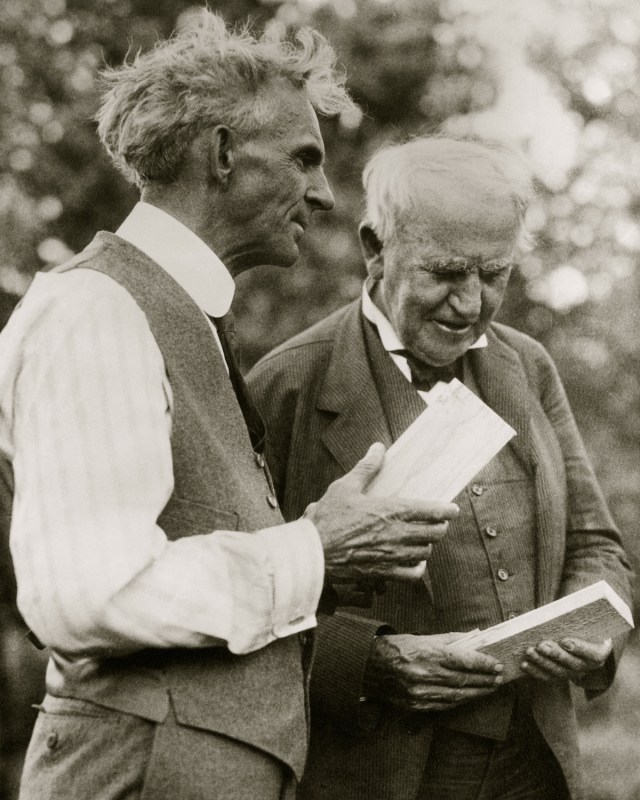

On December 1, 1913, Henry Ford fully implemented his moving assembly line. It was an innovation that would transform not just the auto industry, but industry in general. It reduced both the time and labor required to complete a car. Oh, and his workers absolutely hated it.

There were many reasons to hate it. Suddenly teams no longer assembled entire cars. Now workers just focused on a single task. For veterans of the earlier process who were regarded as skilled laborers, this was a big step back. Finally, there was a surrendering of control, and not even control to another human. The frustration was summed up by a worker in the 1920s who declared: “The machine I’m on goes at such a terrific speed that I can’t help stepping on it in order to keep up with the machine. It’s my boss.”

Of course, there were upsides too. More workers were needed. (In 1913, Ford hired more than 52,000 of them.) Wages improved too. Suddenly workers could make $5 for an eight-hour day, when the usual rate was about $2.25 for nine. (Of course, Ford could afford to be generous: His net worth at the time of his death would be approximately $200 billion today.) Ultimately, those who joined Ford knew they made a trade-off: better pay, less freedom. To read more about this transformational moment, click here. To see assembly lines in action, watch the video below.

—RealClearLife Staff

This article was featured in the InsideHook newsletter. Sign up now.