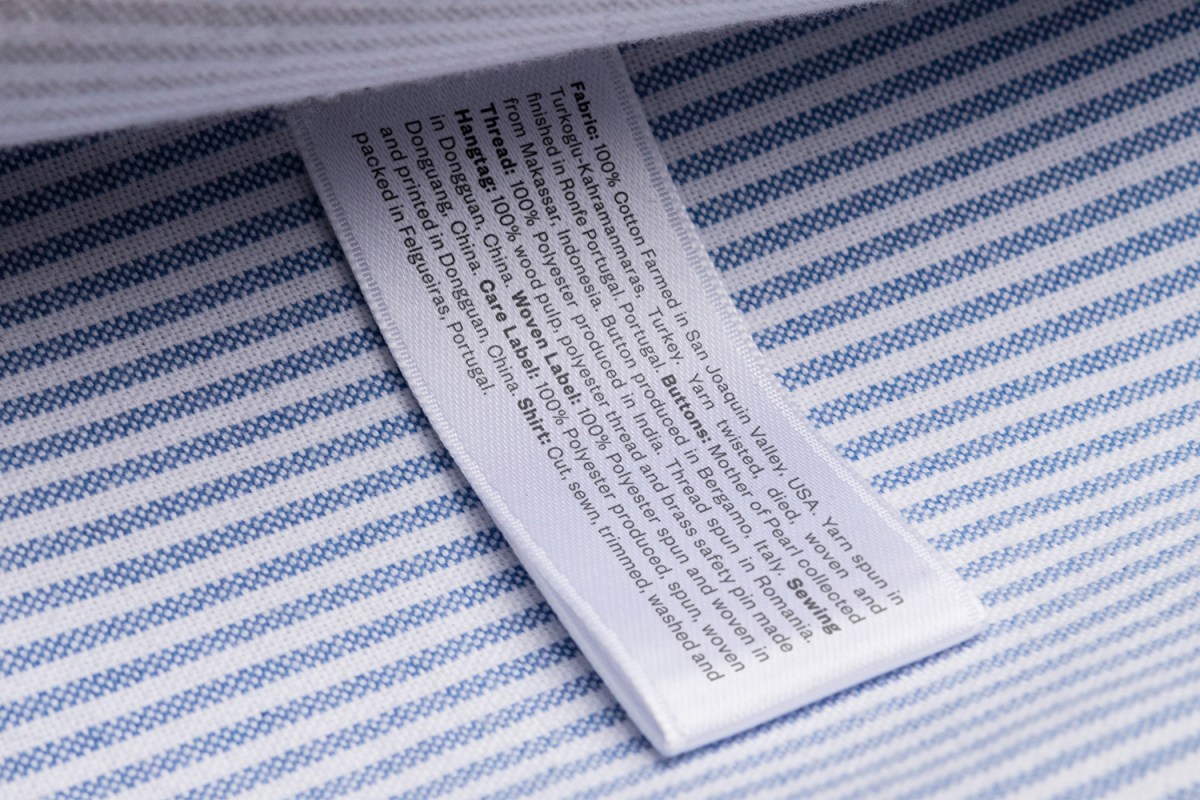

Look at the tag on the inside of your shirt. It will likely say the country where the garment was made and the materials it’s made from. But was made it sustainably? Humanely? With eco-friendly materials and processes? You certainly won’t be able to tell that from the tag, or even the label’s website. After all, who knows what’s going on in the fields where the cotton was originally picked?

Asket knows, or at least it’s doing its damndest to find out. The Swedish menswear company, founded in 2015 by Jakob Dworsky and August Bard Bringéus, doesn’t take much stock in “sustainability,” the blanket term used across the fashion industry that’s potent enough to make consumers feel good about buying clothes but vague enough that brands aren’t compelled to take real action. That’s why they’re pioneering a new idea: traceability, which provides a detailed receipt of where, how and by whom the garment was made. If you buy a hoodie from them, they’ll tell you where the cotton was farmed, ginned and combed in Turkey, where the pocket lining yarn was spun and twisted in India, and where the raw material for the aglets (those little sheaths at the end of the hood drawstring) was sourced in France.

If you say that sounds like overkill, we might have agreed with you a decade ago. But the ugliness that persists in the fashion industry can no longer be swept under the rug, from the recent revelations around Uighur slave labor in cotton production to the unimaginable waste (a UBS report found that of the 100 billion items of clothing made every year, more than half are thrown away, then burned or sent to landfill within a year) to the constant carbon emissions. Is it too much to ask that the clothes we wear do no harm? Or less harm, at least?

When looking at all these issues, that can seem like an insurmountable goal. But when looked at it in the micro — How does that simple button-up shirt you buy online show up at your door? — it seems more manageable. And Asket is trying to do their part by tracing the origins of their garments, showing the impact of them (from water to energy to CO2), detailing the cost and attempting to offer what they call “full transparency.”

We recently chatted with Asket’s Jakob Dworsky about all of this, from the challenges that his company is facing in holding themselves accountable to the biggest problems in fashion that no one is talking about (spoiler: those clothes made out of recycled plastic bottles may not be as green as they seem). Consider this a fast lesson in slow fashion.

This interview has been edited and condensed for length and clarity.

InsideHook: How has business been during the pandemic?

Jakob Dworsky: We can count ourselves lucky. We had a scare when the first news came around March last year and there were a couple of weeks where I think people were focused on buying toilet paper rather than clothing, but then it picked back up again. So we had a pretty good year. There have been some challenges in the supply chain, both Portugal and Italy, where we produce a lot of our garments, have been hit quite hard during different periods, so there’s been delays which has caused some stock running out and things like that.

During Earth Day last month we were inundated with all these messages about clothes that are “sustainable” or “climate friendly” or “climate neutral.” It seems like the average consumer is faced with a lot of terms to sift through. So why is “traceability” something that people should care about?

First of all, I completely agree that there are so many buzzwords out there and it is extremely hard for even a customer who wants to shop consciously, [as they are] bombarded with different kinds of messaging. Even for me working in the industry, it’s hard to debunk all the claims. But traceability for us is part of the grander umbrella of transparency, which is all about giving the customer all the facts and enabling them to make more informed and better decisions when they actually need to buy something.

Transparency is as much about where, how and by whom something is made, which is what we call traceability, but also about what they cost you, what they cost us and what they cost the planet. But traceability in itself is really the foundation of that because how could you know that a garment is climate neutral or sustainable if you don’t know where it’s made and how, and by whom? Making those claims without traceability, I would say, is borderline greenwashing. I mean, if you turn it around, the lack of traceability is what has allowed the supply chains to remain quite dirty. It’s what allowed something like Rana Plaza to happen in the first place, because it removes accountability.

We believe it’s crucial that the customer knows and understands the journey of a garment and the massive amount of resources and work that is put into them, because that’s the only way for someone to appreciate them and make sure that we turn them from disposables into investments; and that we then, in turn, actually start taking care of them and minimize our consumption.

I guess the disclaimer would be that traceability in itself doesn’t mean that you’re necessarily more sustainable. It just means that we’re aware where it’s made and how, and then you can start working on lowering your impact based on that. But of course, if you’re working with traceability and disclosing that, I would say you are working more responsibly, otherwise you wouldn’t put that [information] out there. If you’ve got nothing to hide, then you can do that.

This is a really big question, but I think for a normal person buying a pair of pants, they might think that traceability is easy. But can you, in a simple terms, talk about why it’s so difficult to trace a garment to its origins and offer all of that info?

I’ll give it a try, and let me know if it’s too many insider terms or anything. At the top level, it’s about the supply chain and fashion being extremely complex and very dispersed globally. So it’s huge and it’s everywhere, and a garment travels through a lot of different countries and comes from a lot of different origins that are put together in various places. So that makes it inherently difficult.

Also, it’s historically opaque, with few actors actually willing to share their secrets and their information, and that can be for various reasons. One of the things we’ve run into is competitive reasons — that if you start asking a factory about this, they may think that we’re just trying to understand how they’re making it so that we can go and source it somewhere else or make it ourselves or cut them out of it somehow, because there’s not a lot of IP in fashion. You can’t protect a lot of it. Or they’re hiding something. Or in many cases, the suppliers don’t really know themselves [where their materials come from]. They haven’t done the work because it’s quite a recent question for them.

To also paint the picture, there are so many tiers in this. Many brands only know the first tier that they’re working with, which is normally the cut-and-sew factory. In simple terms, say that we want to buy a thousand T-shirts … but that factory, they source the fabric from another factory, and that factory sources the yarn from a third factory, which sources the raw material from a bulk auction somewhere where cotton from various farms has been mixed together, and by then you’ve lost sight of things.

As a [clothing] brand, they buy the whole [garment] from one supplier and they get one invoice and they quite often don’t know the other steps. So it’s a lot of steps and a lot of work. It’s very hard for many brands because it requires an immense amount of time and resources. If you are developing and launching thousands of garments each year, it’s probably going to cost you too much to do it. The reason we’re able to do it is because we have a permanent collection and we release five garments a year and we can really spend that time on them because we also work long-term with our factories.

You originally had a goal of all your clothes being 100% traceable by 2019, but you haven’t quite made it. Can you talk about the challenges you’ve faced trying to get to that point?

I mean, 100% obviously was overly ambitious in retrospect. We’ve been working very hard, but we’re still only at, I believe, 86% currently. And the biggest challenge really has been getting down to the raw material, which ties into what I was talking about before because the way raw material is normally sourced is through big auctions and it’s traded as a commodity, essentially. And the people who buy that commodity and sell it, they are blending from different sources. It’s very tricky to get to one specific farm. You can get a region, perhaps. But even if you find a farm one year, the next year maybe it rained a bit less so the quality of the cotton is not the same, so you have to move to another farm and that makes it even harder.

Sometimes it’s a matter of volume. If you’re going to have your own proprietary production line with a mill, you need to have volume, because they are normally producing really large amounts of yarn that goes out to several clients. Actually, one of the categories where we did reach 100% was in the merino wool products, which required us to buy four tons of wool to be able to have that source from one place and go to our yarn supplier. That was quite a challenge. At the time, that was at least two or three times more than we would’ve normally needed or bought, but we took that on and are super happy that we did.

Those are, I would say, the major challenges, and we’re still working on quite a few of the pieces. I think on 50% we have reached 100% [traceability] or just about. Maybe there’s something missing on one of the trims, like “Where does the zipper iron come from?” or something like that.

One thing I find really interesting about your company is that a lot of other brands will pick a lane. They’ll focus on climate or pollution or labor. You guys are pulling all these things together. People have some idea of the problems here — the emissions caused by certain garments or certain materials that historically have bad labor practices — but are there issues in fashion that you think normal consumers are still in the dark about?

As a brand we believe — and the lane we picked, as you put it — it’s really about the consumption problem. That is the underlying problem feeding all of these things, and I feel that is not completely understood. People are still hoping that we can shop our way to sustainability and that we will solve this with technical advances. But in truth, those advances made in the industry have historically and continuously keep being eaten up by the increased consumption. So impact is rising, even if we’re slightly more efficient in some areas.

On a more particular topic, I feel that the plastics issue is really a big problem and people don’t talk about it so much. Recently, plastic has popped up as almost a positive fiber when we’re talking about recycled plastics, which is, if you dig into it a little bit, I would say that’s really not the case. At the beginning, the introduction of synthetic fibers and low costs really led to a decrease in garment prices, and that’s linked to the rise in consumption and that race to the bottom in pricing. Today we are looking at 70% of all the textile production is synthetics, which is insane. I don’t think people realize that. But it’s in almost every garment you look at if you go into a store.

Now with recycled polyester, in particular, that’s actually being marketed as a super positive fiber, like we’re solving the plastics issue. In reality, sure it’s recycled, but it’s not really recyclable. So you’re taking plastics out of a closed-loop system in the bottling industry and you are putting it into garments that are eventually bound for landfill and incineration, instead of being used for new bottles. In turn that drives up the cost of recycled plastics, and actually there’s too little of it these days. So the bottling industry will use more virgin plastic. So we’re really not solving anything here.

To top that off, we have the whole microplastics issue. Those fibers are being shed into nature and into water and that’s really bulking up over time. So that is a topic that I would really want to be more explored. Now people are rising up and talking about it because the lobbying has been so successful that [the United States is] about to put in legislation where recycled plastics are favored ahead of regenerative materials or renewable materials like cotton or wool or silk or even linen.

What’s your long-term goal for the company? Is it to get to a 100% traceability and operate at that point? Or are you more looking to be an influential force in the fashion industry and have people adopt your model?

Can I say both? Definitely the main goal is that we want to drive change. We want to have greater influence and we want to do that both by influencing our customers, but also we see ourselves as a pathfinder in a way. If [other companies] look at us and follow, we’re super happy — that’s the best way for us to have an impact, and that’s going to be much faster than trying to do it on our own. But I would say, definitely, we are aiming towards 100%. Might be a pipe dream, but in the long-term, I even see us trying to ensure that by having our own factories or farms. That’s how far I would say I’m willing to go on this.

This article was featured in the InsideHook newsletter. Sign up now.