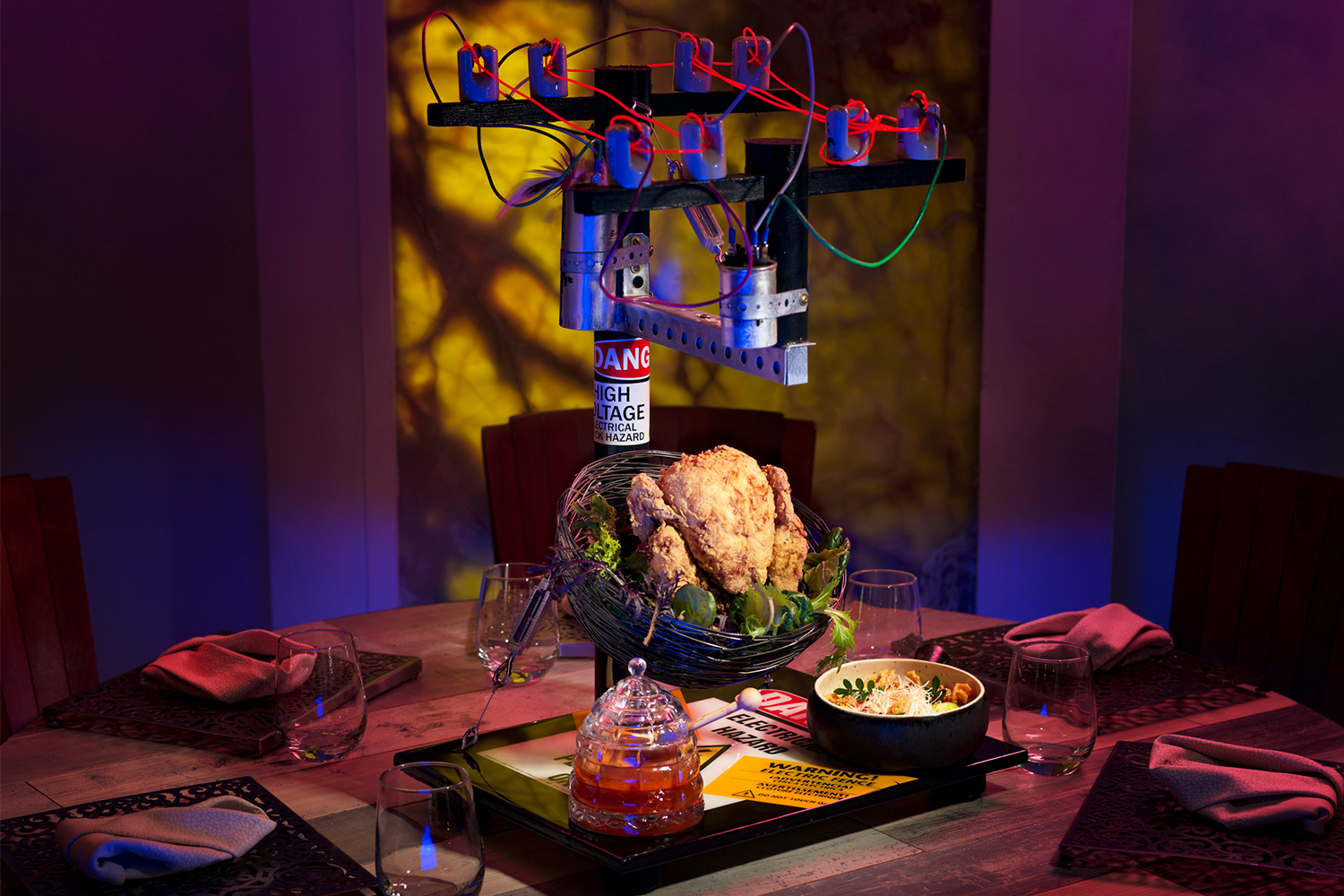

At Barton G in Miami Beach, food is both entertainment and art, and over-the-top decadence is the name of the game. The restaurant spends close to $160,000 on menu development each year with an eye toward creating highly theatrical dishes. (It helps to know their side business is designing high-energy events for blue-chip brands like BMW, Microsoft, the NFL and the PGA.) Think colorful chopped salads that arrive by wheelbarrow, Wagyu steak tartare served by a martian, a four-foot-tall upside-down ice cream cone for dessert — or a whole fried hen, served under an electric fence.

“We wanted to come up with a fried chicken dish, so the chef came up with the concept of frying the whole chicken instead of in pieces,” Amin Noorzai, Barton G’s VP of restaurant operations, tells InsideHook. “The whole chicken was a little big, so we went with a cornish hen. And then we were experimenting with how we could fry it all the way through so it was cooked through but still crispy on the outside. Once we nailed the dish, we had to come up with a fun presentation, so we went with the electrical fence.”

It feels like nothing is off limits when it comes to Barton G’s ambitious custom-designed set pieces and, as Noorzai notes, nothing really prepares you for their dining experience, either.

“You can’t really explain to people what Barton G is,” he says. “You have to just go see it for yourself. It’s very tough to put into words what we do.”

We decided to ask anyway. Below, he talks us through how, exactly, they spend that $160K.

Research & Design: $25,000

“Every year we come up with new presentations. Certain signature dishes like our lobster pop tarts and popcorn shrimp will stay on the menu, but we do a big overhaul each year. As soon as we launch a new menu, we get started on the next one. It’s a fun process for us, because it always keeps our mind going, and we are constantly thinking of the next coolest thing. It starts with me, our Corporate Executive Chef Rod Chikitov and Corporate Pastry Chef Marta Kantorowicz. Sometimes we come up with a dish first, like, it would be freaking cool to serve a whole fried chicken. Or sometimes we come up with the presentation first, and then we need to come up with an idea of what food would match. It’s pretty organic. There’s no black and white. We have good chemistry and love bouncing ideas off each other. Our process involves a lot of tequila and some weed to open our minds a little bit.

“Once I started working for Barton, it really changed how I think. I go to Home Goods, and it’s like going to Disneyland for me. Your mind just changes. You might see a candle holder, but I’ll be thinking about how I can serve food or a drink in it. I can never walk into a store and look at things in a normal way. I get FaceTimes at all times of night and day from my team, with ideas for new presentations.”

Tastings: $6,000-$10,000

“After we have our prototypes ready, we go into a meeting with Barton and show him the new presentation and dish, and he either gives us a thumbs up or thumbs down. He approves everything before it goes on the menu.

“Most of our heartbreak is usually with Barton. We put a lot of time and effort into something and, as a team, we think it’s our next big hit. And within five minutes in front of Barton, he hates it and wants to move on. After many years, we have learned what he likes and dislikes. He doesn’t like anything plastic. No plastic mannequins. At the end of the day, he wants everything to be as custom as possible. We have to put our signature on it.”

Materials: $70,000

“Part of our challenge with building stuff is that we make one prototype, and that might take us three months to do. And if Barton loves it, when we turn around to go buy 50 Buddhas, all of a sudden they don’t have it. To find the exact size, height, width and weight is very difficult. So we know we have to tweak it here and there to get it as close to the original prototype as we can. The supply chain problems are absolutely real for us — during COVID, it became even worse.

“For example, our new vintage carnival cart has funnel cakes, three dipping sauces and all of your deep-fried carnival favorites: deep-fried Oreos, Reese’s Pieces and Snickers. It’s all served on a red carnival cart with lighting and a tent. That was 100% made from scratch — buying screws, wood, glue and everything was done in house, then painted.”

Labor: $30,000

“We have a small team, so labor includes two artists and a carpenter. That’s it. We’re a small but efficient team. Our carpenter is so creative, and he’s like the engineering department, figuring out how to build things with our vision. Like gutting this old-school vintage 1980s boombox for my new favorite cocktail, and tricking it out with music and lighting. Guests love this drink because it’s a throwback and our artists painted on some custom Barton G graffiti.”

Transportation/Shipping: $25,000

“Shipping costs go into the packaging of the stuff to ship to L.A. since we build everything in Miami. [Ed. note: After the menu is developed at Barton G’s Miami Beach flagship, it’s deployed at their second location in L.A.] Some of the items are fragile or have weird shapes, so you can’t just stack them. A lot of the expense goes into wrapping. We usually do ground shipping because it’s much less expensive. Give or take, it might be 150 to 200 pieces each year. For example, the Buddhalicious is our number-one selling cocktail, so L.A. will get 12 presentations of that.

“My biggest fear when we come up with presentations is that people look at it as just a gimmick. We really put a lot of thought and time into the food too.”

This article was featured in the InsideHook newsletter. Sign up now.